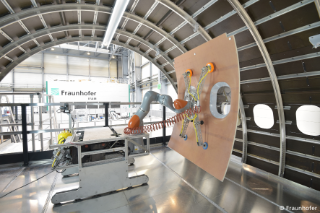

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM l Stade is presenting its forward-looking R&D portfolio for the first time at the "ILA Goes Digital 2020" (www.ila-berlin.de/en/node/5174) until July 31, 2020. The focus of the digital trade fair presence will be the live event "Automation in Aerospace Industry @ Fraunhofer IFAM" on July 1, 2020.

more info Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM