COUNTERING DIFFUSION AND EMBRITTLEMENT IN THE STORAGE AND TRANSPORT OF HYDROGEN | Green hydrogen will play a decisive role in a successful energy transition. The development of new hydrogen technologies requires techniques and processes that enable the safe production, storage, distribution and use of hydrogen. Central material science challenges are the diffusion of hydrogen and the associated embrittlement of used material. The "Plasma Technology and Surfaces" department at Fraunhofer IFAM is researching how surfaces can be protected against this diffusion and embrittlement by treatment with plasmas or lasers. The focus is on internal coatings for tanks and pipes, but possible applications for electrolysers, bipolar plates, and fuel cells are also being investigated.

more infoMagazine

-

-

Elektrischer Hochspannungsfunken

ARC-PROOF DC CONNECTOR SYSTEMS FOR HIGH-VOLTAGE APPLICATIONS IN BUILDINGS | In a world where practically all consumers require direct current (DC), DC networks offer immense advantages. Modern semiconductor technologies enable safe utilization, which is accompanied by the advantages of increased efficiency at lower costs. Fraunhofer IFAM has developed a concept for a very compact plug-in system that can transmit high DC power and ensure the required safety through the use of electronics and software.

more info -

CHARGING MANAGEMENT FOR ELECTRIC VEHICLE FLEETS - SOLVER-BASED, CUSTOMIZED AND COST-EFFICIENT | The experts in the "Research Data" unit at Fraunhofer IFAM use a specifically developed simulation environment to determine the most cost-effective solutions for operating electric fleets on site for individual scenarios.

more info -

Electric wires and district heating tubes

STUDY "IMPROVING THIRD-PARTY ACCESS TO DISTRICT HEATING NETWORKS" | As part of the study “Improving third-party access to district heating networks” commissioned by dena, experts from Fraunhofer IFAM have developed a concept that structures the integration of external heat generators, so-called third parties, into large heating networks through regulated processes. This takes into account the requirement of the Renewable Energy Directive (RED III), according to which operators of district heating or cooling networks with a capacity of more than 25 MWth are required to grant third-party providers of energy from renewable sources and waste heat and cooling access to the network or to purchase and feed in the energy (Article 24, Paragraph 4b).

more info -

Von links nach rechts: Stator mit Gehäuse des Referenzmotors, Originalrotor mit vergrabenen Magneten, 1. Optimierungsschleife: Rotor mit Viertelringmagnet, 2. Optimierungsschleife: Rotormagnete in Flusssammleranordnung

ALTERNATIVE MAGNETS FOR ELECTRIC DRIVES | The conservation of raw materials is becoming an crucial aspect of the development of electric machines. For instance, rare earth elements are employed the production of magnets for synchronous machines. However, these elements are not only expensive but also in limited supply, which is why they are mostly imported from China. As a result, electric machine manufacturers are actively seeking alternatives. At Fraunhofer IFAM, research is being conducted on materials that are not only more cost-effective but also reduce dependence on rare earth elements. This is of great interest to the industry, given the extreme price fluctuations and China's dominance in rare earth mining.

more info -

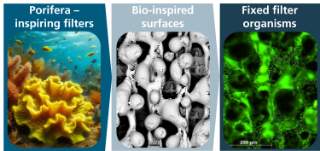

Our environment is under increasing pressure from chemical pollutants contaminating soil, water, and air. Particularly concerning are persistent substances such as per- and polyfluoroalkyl substances (PFAS) and pharmaceutical residues. These belong to a group of over 4,700 compounds whose effects on human health and ecosystems remain largely unknown. Despite advanced wastewater treatment technologies, any of these pollutants still enter the environment, threatening fragile ecosystems – even in remote regions like the Arctic. This is where the R&D project DeDrug-Bio comes in. By leveraging biohybrid filtration systems, harmful substances can be removed efficiently and sustainably – an innovative approach that seamlessly integrates nature and technology.

more info -

COMMON CHALLENGES FOR ENERGY SUPPLIERS, COMMUNES AND THE HOUSING INDUSTRY | The sustainability goals at federal and state level in Germany require a climate-friendly heat supply. The goal of a climate-neutral building stock by 2045 can only be achieved through an innovative and sustainable heat supply. Therefore, energy suppliers and communes as well as the housing industry must face common challenges and work together in order to master them. Fraunhofer IFAM provides support with strategic planning of the heat supply and takes into account the various possible supply options and their economic efficiency.

more info -

BioRUHM

PROJECT “BioRUHM”: REACTIVE URETHANE-FREE HOTMELT ADHESIVE | Reactive hot-melt adhesives (RHM) based on isocyanate are increasingly being used due to their exceptional properties, from packaging to automotive construction and technical textiles. However, the composition of these urethane-based adhesives also involves risks, e.g. the release of hazardous isocyanate. In the “BioRUHM” project, Fraunhofer IFAM is working with project partners to develop a urethane-free concept.

more info -

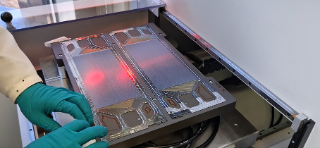

Bipolar plates from the ZSW are fixed in the printing nest using negative pressure. The structure of the printing nest and screen allow simultaneous coating on the anode (left) and cathode side (right) for each printing process. For printing on the reverse side, the bipolar plates are returned to the screen printing process after curing.

METHODS FOR APPLYING SEALANT TO BIPOLAR PLATES USING SCREEN PRINTING | Fraunhofer IFAM is your competent partner for innovative research services in the field of fuel cell production. In addition to industrial projects in this context, we are active in public research projects - including the National Action Plan for Fuel Cell Production (H2GO). The National Action Plan maps the key sensitivities of the value chain in the production, stacking and recycling of substantial fuel cell components. Fraunhofer IFAM is, among other things, researching the use of the screen printing process for applying sealants to bipolar plates, which has several other advantages in addition to reducing production costs.

more info -

SALT SPRAY, CROSS-CUT AND G1C TESTING ACCORDING TO NADCAP | Since March 2020, parts of the laboratories at the Bremen site have been recognized under the Nadcap conformity system relevant to the aviation industry. The successfully obtained Nadcap "accreditation" as an independent testing laboratory in the field of chemical processing applies, among other things, to the cross-cut test according to DIN EN ISO 2409 and the salt spray test according to DIN EN ISO 9227, which are important for coatings. In the field of Non-Metallic Materials Testing (NMMT) recognition has been valid since June 2021 for the testing of composite materials (CFRP) according to AITM 1-0053 (G1c procedure).

more info

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM