Technologies for transport and storage of hydrogen

As a versatile energy carrier, hydrogen will play a key role in the long-term success of the energy transition. Fraunhofer IFAM is working with project partners in the flagship hydrogen project TransHyDE to further develop and test technologies for the transport and storage of hydrogen. LOHC technology (liquid organic hydrogen carrier) plays an important role in this.

Transport chain for green hydrogen

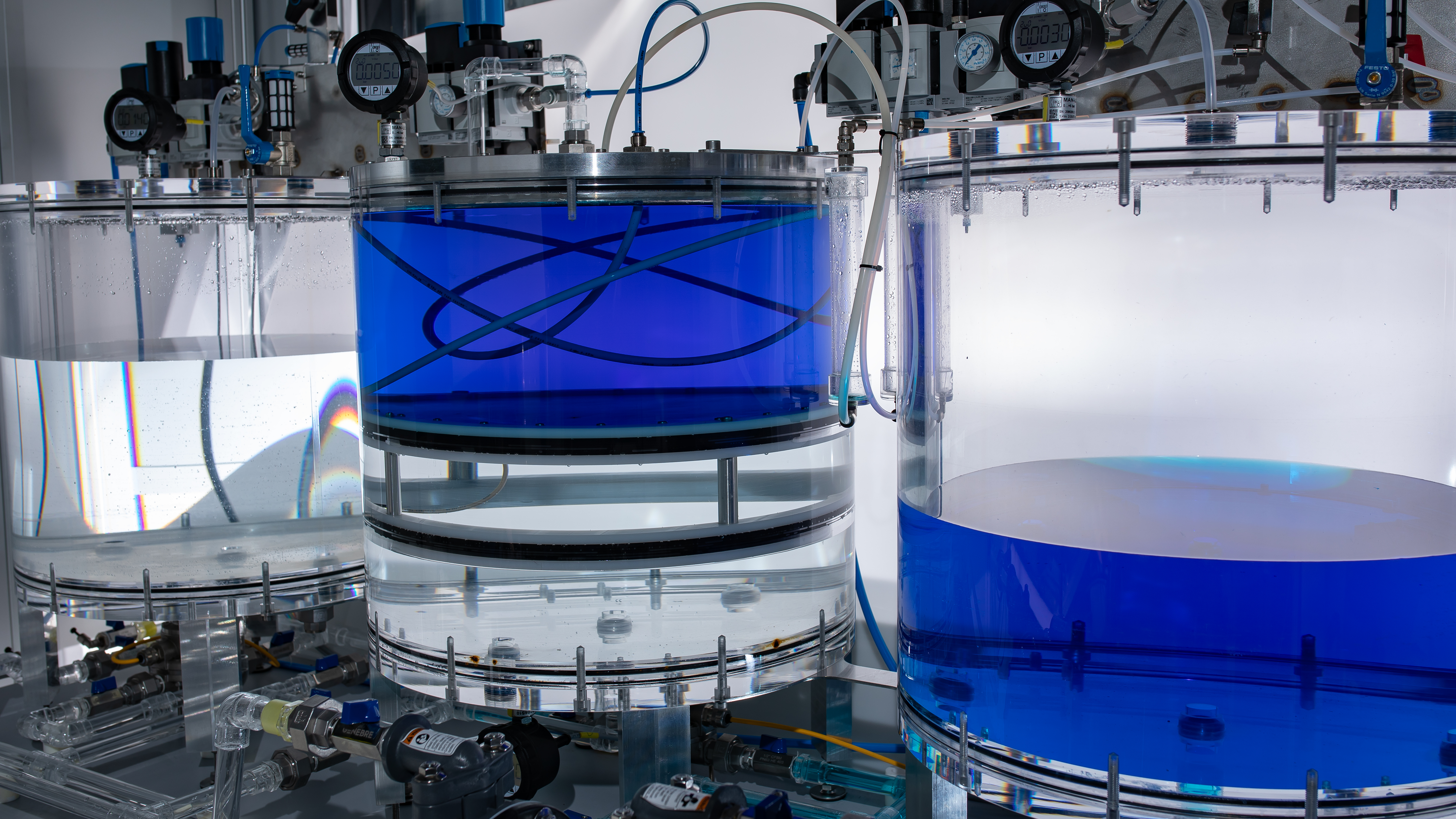

As part of the developments in the flagship project TransHyDE, possibilities of transporting hydrogen in gaseous form, as liquid hydrogen, and chemically bound in ammonia or in LOHC (liquid organic hydrogen carrier) are being investigated. In the TransHyDE project "Helgoland", project partners from industry and stakeholders from the island of Helgoland, together with Fraunhofer IFAM as the research institute, are researching and developing a transport chain for green hydrogen based on LOHC technology. The transport of hydrogen produced on the North Sea with wind energy via Helgoland to Hamburg is devised as a model case. Fraunhofer IFAM is currently working on more than a dozen different research topics related to this task.

Advantages of LOHC technology over other transport options

The basic idea of the LOHC technology, further developed by the project partner Hydrogenious LOHC Technologies GmbH, is to chemically bind the gaseous hydrogen to a liquid carrier substance (LOHC), transport it to the destination and extract the hydrogen there, whereupon the LOHC can be used again for the next transport. The transport of the oil-like carrier substance is designed for the use of existing infrastructure and avoids the challenges of other transportation options such as high pressure, low temperatures, explosion or fire hazards.

Hydrogen pipeline coatings

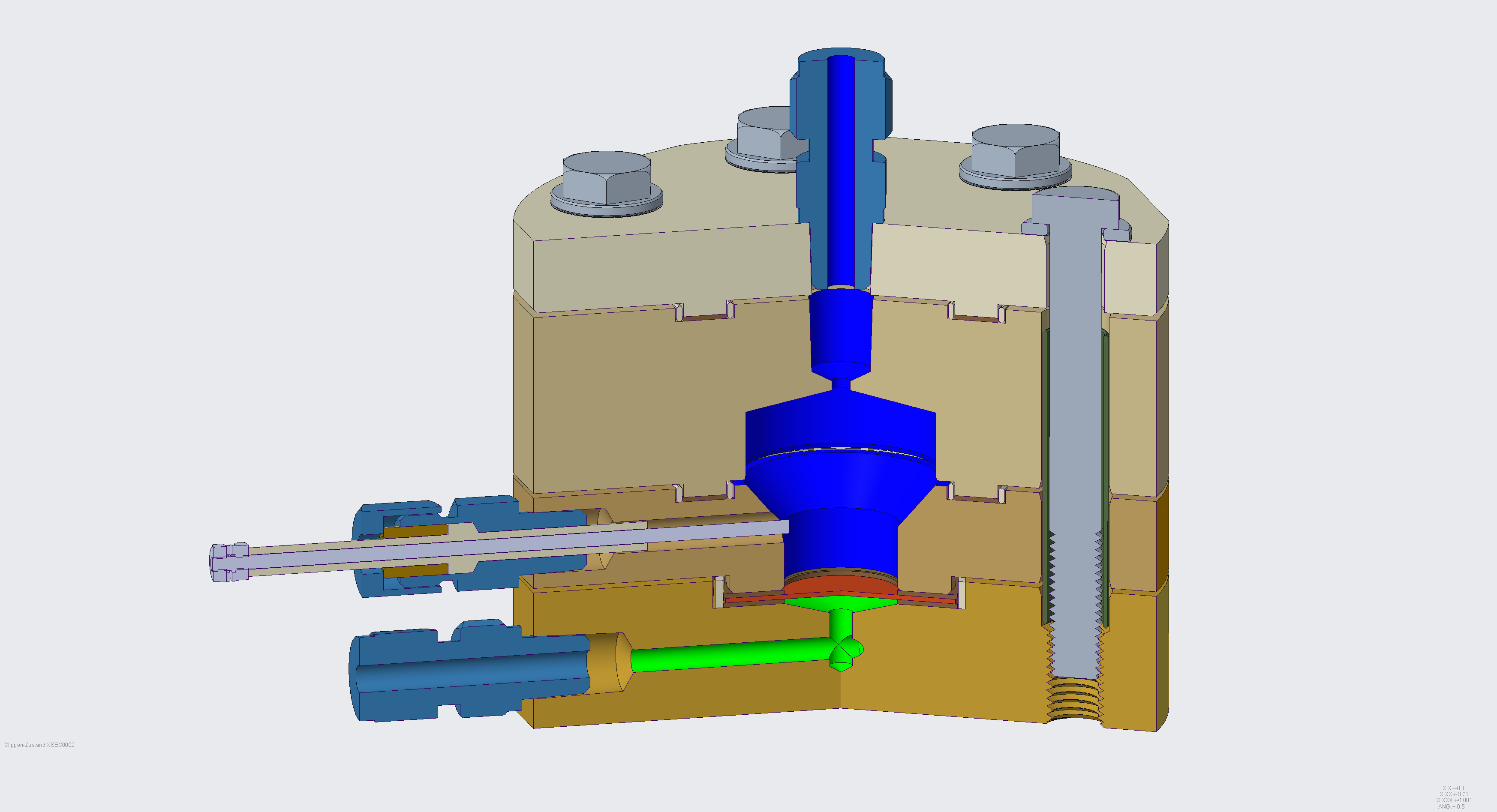

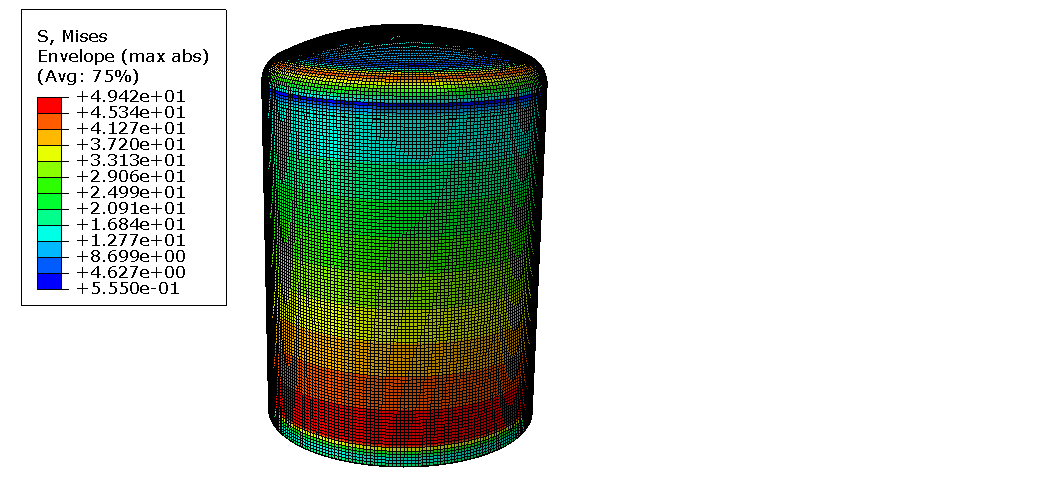

In the first sub-step of the hydrogen transport chain, the hydrogen arrives as a gas from the producing wind turbine to the hydrogenation plant on Helgoland. Several of our research tasks address issues related to the pipeline on the seabed. To improve sustainability, we are developing biocide-free anti-fouling coatings and investigating which substances are released into the environment by anti-corrosion coatings. The permeation of pressurized hydrogen into metallic materials can lead to undesirable hydrogen embrittlement even in the smallest quantities. To reduce this damage, we develop special barrier coatings. To test the effectiveness of the coatings and for further research into hydrogen embrittlement, a test facility is being set up which will allow experiments to be carried out under simultaneous exposure to compressed hydrogen and mechanical loads.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM