Adhesive bonding as an alternative for assembly and repair bonding for offshore applications

The use of adhesives in the maritime sector offers a promising alternative to other joining methods. Disadvantages associated with joining technologies such as screwing or welding are eliminated and possibilities for long-term stable adhesive bonds of up to 25 years are created. Fraunhofer IFAM is continuously further developing the topic of adhesive bonding in the maritime field within the framework of publicly funded projects and is developing individual processes for its industrial customers.

Challenges for adhesive bonding in the maritime sector

Subsequent installation of secondary elements such as half-shells, support systems or sensors, or the repair of offshore installations such as wind turbines or boat landings pose various challenges. The maritime environment is characterized by its harsh weather conditions, such as wind, low temperatures, salty air and seawater.

The cold bonding process offers an alternative to conventional joining methods, which, for example, can securely adhere different materials to each other without the time-consuming removal of coatings. Thus, adhesive bonding does not require any steps that would damage coatings for corrosion protection (e.g. through high heat input or metallurgical notching) or damage the wall thickness of the respective structures.

Adhesive bonding in the maritime sector can be implemented quickly, safely and cost-effectively. In addition, various potentials are utilized, e.g. with regard to sealing, electrically insulating or conductive effects. In addition to corrosion protection and positive effects due to the water absorption capacity of the adhesives, an elastic adhesive bond can for example offer resistance to wave impact.

Fraunhofer IFAM brings expertise - adhesive bonding as an individual solution for diverse applications

Our experts in adhesive manufacturing develop individual processes for a wide range of adhesive applications in splash zone, tidal zone and submerged zone. In the maritime environment, the portfolio includes:

- Adhesive selection and characterization for an application in the maritime environment

- Acquisition and analysis of thermal, physical and mechanical properties

- Aging tests in the maritime field and in the laboratory

- Exposure of adhesive substrate samples and the adhesive bond in different media, e.g. salt water or liquid organic hydrogen carriers

- The ageing can be application specific, for this purpose an ageing plan can be developed

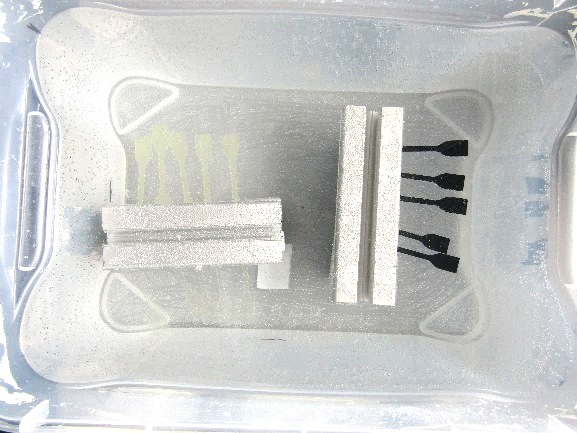

- Development or testing of processes for inductive rapid curing in media (salt water) for adhesive curing that is independent of ambient temperature

- Advantage: temperature-independent, accelerated curing of adhesives

- Development of non-, partially- and automatable concepts for the safe bonding process in the field

- Development and support for the integration of demonstrators or the underwater bonding process for adhesive bonding in maritime environments

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM