Innovative Solutions for Large Bone Defects

In orthopaedic surgery, large bone defects are still a major problem for which there is no optimal therapeutic approach. Current therapy concepts rely on the body's own bone grafts or metallic implants, which are often associated with follow-up operations. This is where the researchers at Fraunhofer IFAM come in and develop materials that are customised to the needs of the human body.

Development of innovative biomaterials for an optimal therapy result

On average, around 800,000 bone fractures are treated in Germany every year. In up to ten percent of the cases, insufficient bone healing occurs, and a segmental bone defect develops. As a result, the bone cannot bear weight and the patients are significantly restricted in their daily life and suffer permanent pain. The reason for the lack of bone healing is often a "hidden" infection. Unfortunately, in order to heal this, it is usually necessary to return to hospital with a follow-up operation and long-term treatment in order to heal the bone defect. In view of the large number of bone fractures that are treated in German hospitals every year, the problem of inadequate bone healing is also a major burden on the healthcare system due to the cost-intensive treatments.

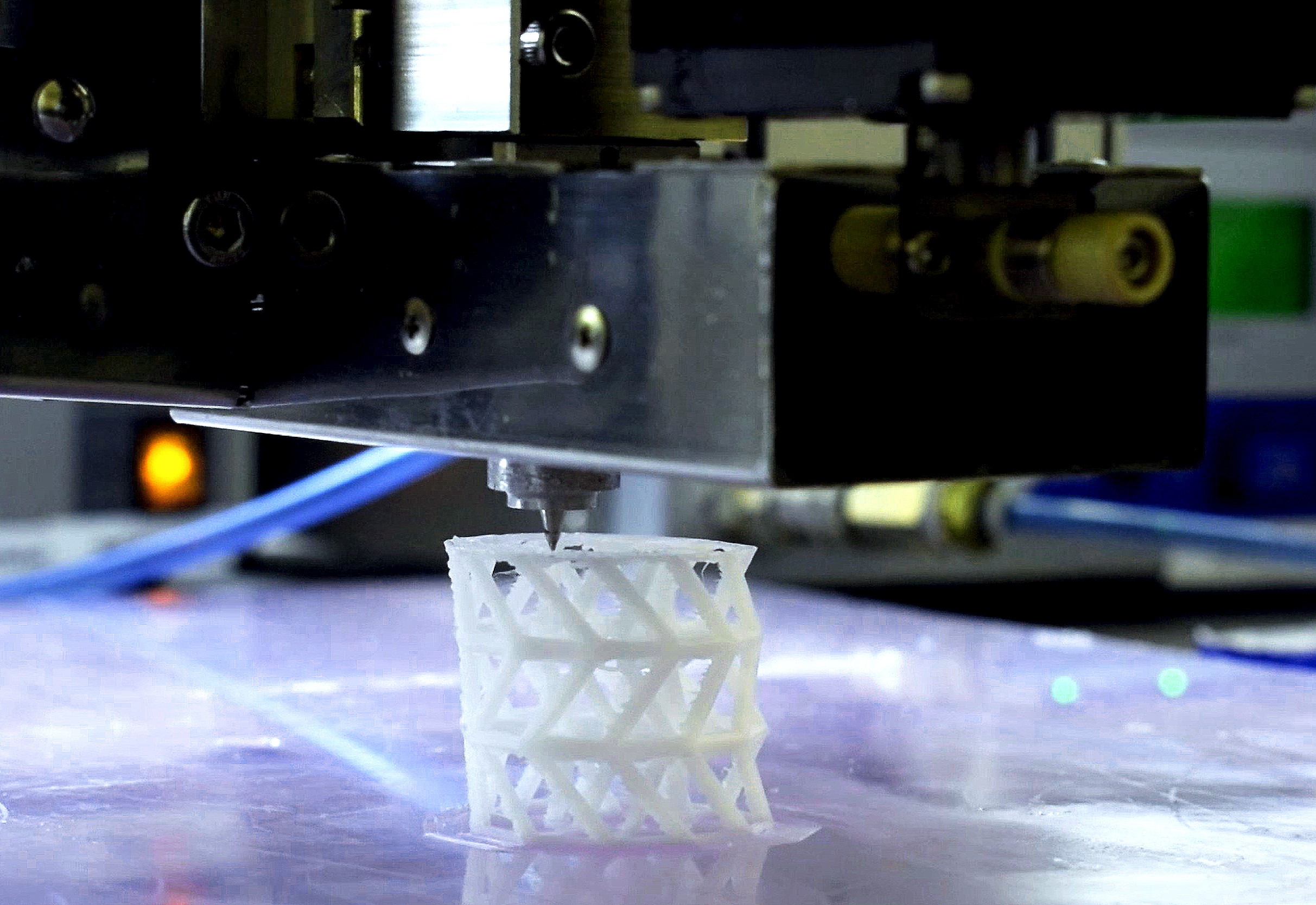

Researchers at the Fraunhofer IFAM in Bremen are working on a promising approach to accelerate the healing of bone defects and significantly improve the success of treatment. Together with the Department of Trauma and Reconstructive Surgery at Heidelberg University Hospital and the company BellaSeno, Fraunhofer IFAM has developed a new type of composite material for a support structure, a so-called scaffold, for the treatment of bone fractures. The composite material combines the biodegradable polymer polycaprolactone with bioactive glass, from which the project partner BellaSeno prints the scaffold using additive 3D printing technology. This is a custom-made supporting and guiding scaffold for the defect site in the bone. The scaffold with its grid structure ensures that the filled bone graft material remains securely in place and new bone can form.

The biological activity of the composite has already been demonstrated in initial in-vitro tests and the desired inhibition of bacterial growth has been proven. The research consortium is currently optimizing the mixing ratio for maximum activity. The technology is being implemented as part of the SCABAEGO joint project funded by the German Federal Ministry of Education and Research (BMBF).

Successful development of the porous biomaterial TiFi

If the mechanical properties of orthopaedic implants are poorly matched to the tissue, this can lead to overloading of the biological interface and to implant loosening. As part of the Fraunhofer spin-off program AHEAD, a project at Fraunhofer IFAM Dresden develops the porous biomaterial "TiFi" made of titanium fibers. The customizable mechanical properties are intended to facilitate adaptation and increase implant service life. In 2023, the project focused on dynamic testing and joining to dense structures. The first tests showed a good fatigue strength of 9.1 MPa (with a still high standard deviation) compared to trabecular titanium (4 MPa). The tests will be continued for statistical validation. In the shear tensile test, connections of TiFi with Ti6Al4V plates created by sinter bonding break in the fiber structure and not at the contact surfacewhich shows good bonding of the material. Fraunhofer IFAM is currently preparing biomechanical simulations and studies on cell colonization together with clinical partners.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM