Robotic, abrasive FRP surface pre-treatment | Automated vacuum suction blasting for cleaning, activating and scarfing of composites

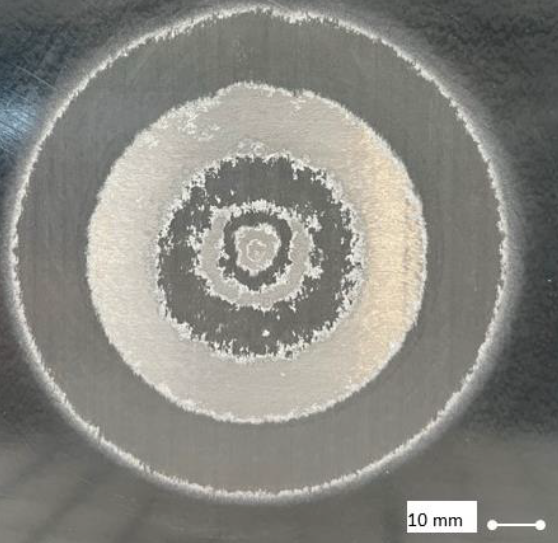

Vacuum suction blasting is an automated and clean process for removing and roughening of surfaces to create adhesion before bonding. The direct off-suction of the blasting particles creates a residue-free surface. The process enables simultaneous pre-treatment and activation of surfaces and can also be used as a removal method of FRP individual layers for scarfing for repairs.

In vacuum suction blasting, a nozzle uses negative pressure to convey abrasive blasting particles onto the surface to be treated and sucks the particles away again immediately afterwards. This roughens or removes the area on the component for surface preparation before bonding, depending on the intensity and application. The surface treatment thus enlarges the surface to be bonded, which is left residue-free at the same time.

The robust principle of vacuum suction blasting enables flexible application. In addition to pre-treatment and activating functions, individual layers can also be removed from components made of fibre-reinforced plastics (FRP) - for example carbon fibre-reinforced plastics (CFRP) - in order to repair the components. Special blasting media and process parameters adapted to the application can be varied accordingly.

The blasting head can be guided by an automation unit, which makes the process more stable and the surfaces are treated evenly.

A good seal between the jet head and the surface is important in order to create the necessary vacuum. The contact application must maintain the distance between the inner jet nozzle and the surface.

Robot-guided blasting process with many advantages:

- integrated emission-free extraction for dust-free environment

- activated surface

- cost-effective and low-energy system

- wide range of parameters

- quality-assuring online monitoring

- replacement of ergonomically demanding manual grinding activities

Automated vacuum suction blasting at Fraunhofer IFAM in Stade

Vacuum suction blasting is an important technology in surface treatment, which the Fraunhofer IFAM uses and develops further. The team in the "Joining Technologies" department is developing methods for the automated pre-treatment and bonding of components. A robot-supported system for vacuum suction blasting is available in Stade.

Current fields of application:

- Pre-treatment of FRP components and FRP surfaces for joining and assembling bonded assemblies of various sizes up to large structure assembly

- Peeling on spherically curved CFRP surfaces. Resin-fibre layers are removed individually in stages, especially when scarfing for adhesive repairs

- Surface treatment before adhesive bonding of aluminium components

- Decoating of rivet heads

- Removal of paint

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM