Digital fingerprint: Forgery-proof identification of components

Digital production requires individual component identification, as this is the only way to digitally link production data with the physical components. Optically readable codes such as barcodes or matrix codes are established methods for recording and tracking components in production and logistics. However, these methods are subject to fundamental limitations in terms of the space required, the surface geometry and structure of the component, as well as the robustness of the marking against damage and manipulation. They are also easy to counterfeit and are therefore only suitable as a security feature to a very limited extent. Last but not least, in some cases modifications to the surface are undesirable, whether for functional, hygienic or aesthetic reasons. This is where Fraunhofer IFAM's fingerprinting process comes in.

Analysis of the surface microstructure of the component

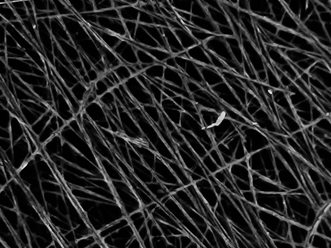

Applied codes are often used to distinguish components that look the same and to assign them a unique number. However, even mass-produced items are unique on closer inspection. Every surface has inherent characteristics that are as unmistakable in their entirety as a fingerprint.

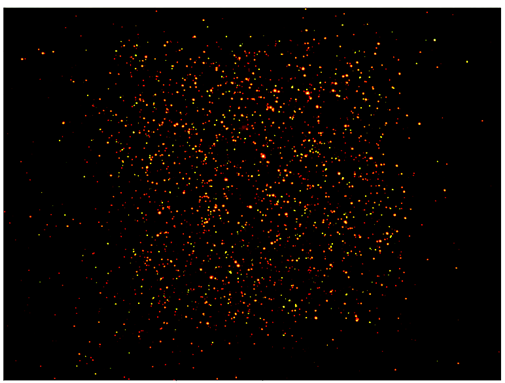

The fingerprinting process developed at the Fraunhofer IFAM makes use of these characteristics. Small irregularities, differences in color, scratches or pores in the material give a particular part its identity. If a surface is actually so flawless that the process reaches its limits, the targeted insertion or application of special particles from Fraunhofer IFAM still allows reliable identification.

A major advantage of the signatures generated in this way is that they are forgery-proof. Combined with the inherent property that the surface does not give away the fact it was scanned and it’s ID registered, opens up areas of application ranging from proof of authenticity and plagiarism detection to security and access control systems.

Robust, redundant, fast and scalable: the advantages of fingerprinting technology

Compared to other methods based on similar principles, Fraunhofer IFAM's fingerprinting technology has some outstanding features:

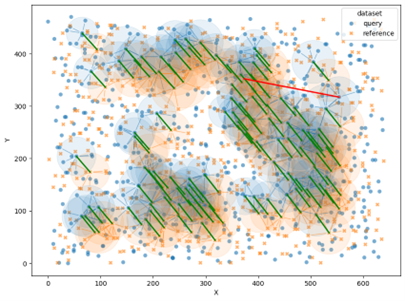

- Robustness: The process is robust against demanding operating conditions. The alignment and illumination of the surface is less critical, even limited soiling and wear of the surface is tolerated.

- Redundancy: Damage to the surface does not impair the detection process as long as a sufficiently large part is still intact. This is due to the high level of redundancy, which delivers clear results even with a fraction of the original information.

- Speed: Parts are identified quickly. Even with very large databases, the process takes well less than a second to complete.

- Scalability: The process can be easily applied to very large quantities of parts without compromising other properties.

The necessary technology can be integrated easily, compactly and cost-effectively and does not place any special demands on process integration. The system is extremely cost-efficient for label-free operation, but even particle labeling is only associated with very low additional costs.

Fraunhofer IFAM combines numerous areas of expertise to offer you a comprehensive range of customized component tracking solutions for your process. The fingerprinting technology has already proven itself and has been successfully implemented in industrial projects.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM