Highly electrically conductive composites for function integration

With the highly electrically conductive polymer composites, it is possible for the first time to offer the user the physical properties of a metal in a thermoplastic polymer. These highly electrically conductive polymer composites thus represent a hybrid class of materials, enabling the user to achieve very high electrical conductivity in a purely metallic form on the one hand. On the other hand, they simultaneously offer the processing variability of thermoplastics, such as injection moulding, extrusion and FFF printing. The polymer composites can be processed in the almost unchanged process of the user's existing plant technology. Recycling and reprocessing are also possible with this class of materials without any problems.

Do you need certain properties of a metal, such as electrical conductivity, in a plastic?

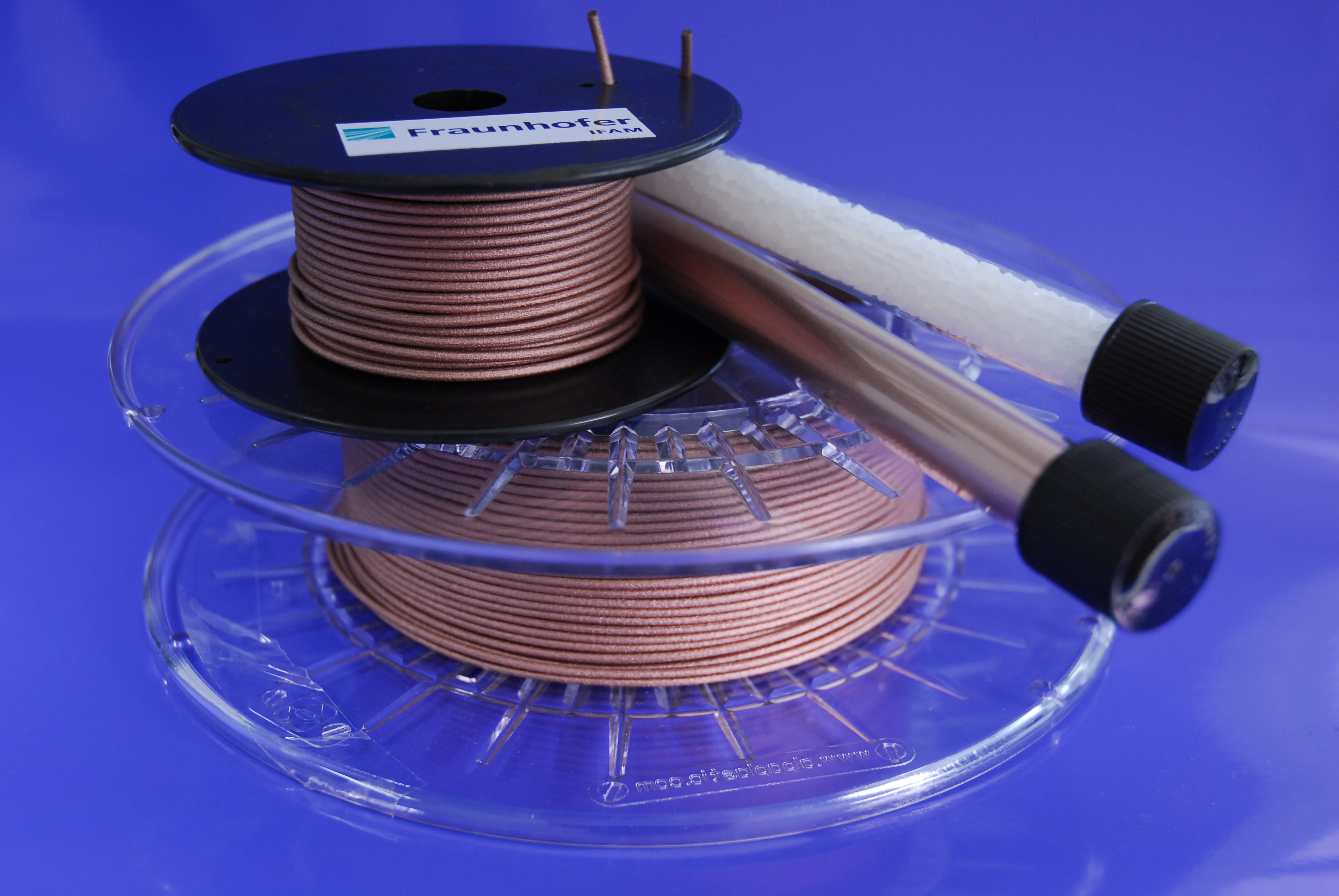

Then Fraunhofer IFAM offers the solution with its developed polymer composites! The special compound technology of Fraunhofer IFAM makes it possible to produce special composites based on a wide range of thermoplastics and elastomers which are, for example, highly electrically and/or thermally conductive.

The resulting combination of functional integration and the known versatility of polymer processability gives rise to a quasi new class of materials on this basis. The integration of highly electrically and thermally conductive fillers in a plastic does not take place according to a "standard recipe", but is produced according to the wishes and needs of the user or according to their intended application profile. IFAM can draw on a broad portfolio of experience with regard to possible combinations of thermoplastic polymers and suitable fillers.

Versatile and individual thanks to special compound technology

With Fraunhofer IFAM's special compound technology, filler contents of around 90 wt.% are possible. The maximum electrical conductivities can be up to 10^6 S/m and, depending on the cross-section of the material, up to 20 A can be applied. Nevertheless, the composites can be further processed with almost unchanged process conditions of the plant technology, be it injection moulding, extrusion or currently often also as filament via FFF printing.

For the users, Fraunhofer IFAM is both a development partner for the corresponding polymer composite and a service provider for more far-reaching issues such as material characterization and testing, the preparation of corresponding feasibility studies, as well as a network partner with regard to the subsequent commercial availability of the composite material.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM