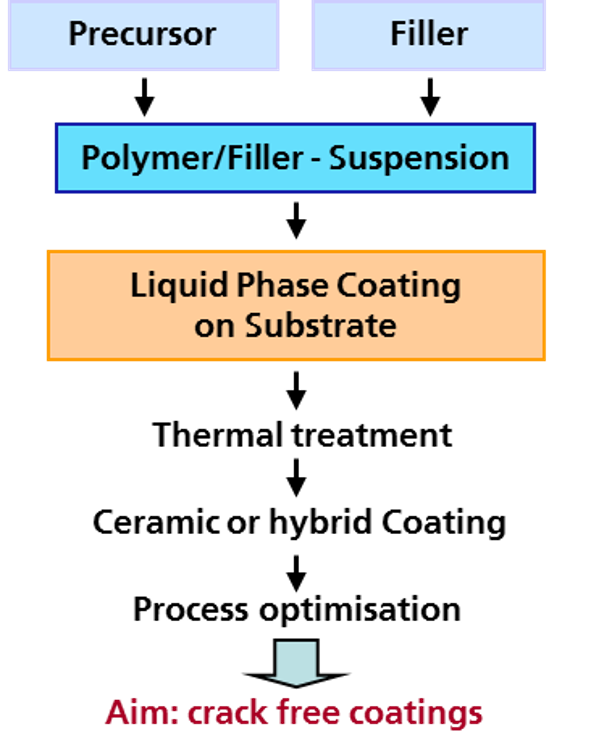

Manufacturing Process

Surface modification by Liquid Phase Deposition (LPD) with inorganic polymers and subsequent ceramisation of the coatings.

Usage of commercial polysilazanes, polysiloxanes, polycarbosilanes, (Si-, Zr-, Al-,Ti-, Mg-), Alkoxides….

Cu-, Ag-, Co-, Ni-Sols, Bioglasses

+ Filler

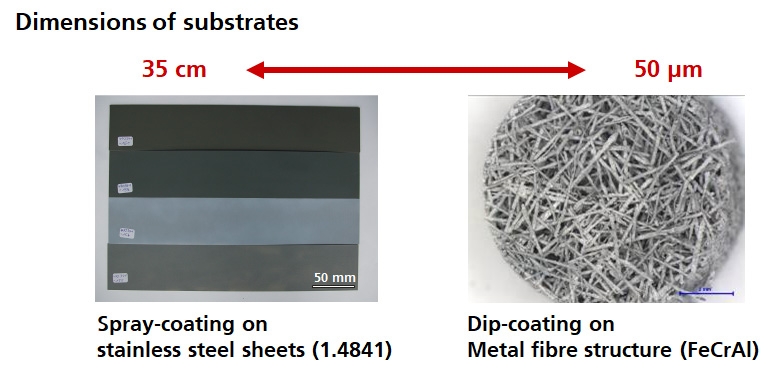

Coating methods:

- Dip-Coating

- Spray-Coating

Possible coating systems:

- Highly porous Sol/Gel coatings

- Dense ceramic coatings

- Self-organised coatings via bloc-co-polymers

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM