Characteristics

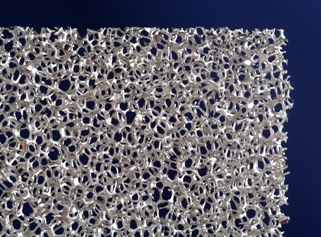

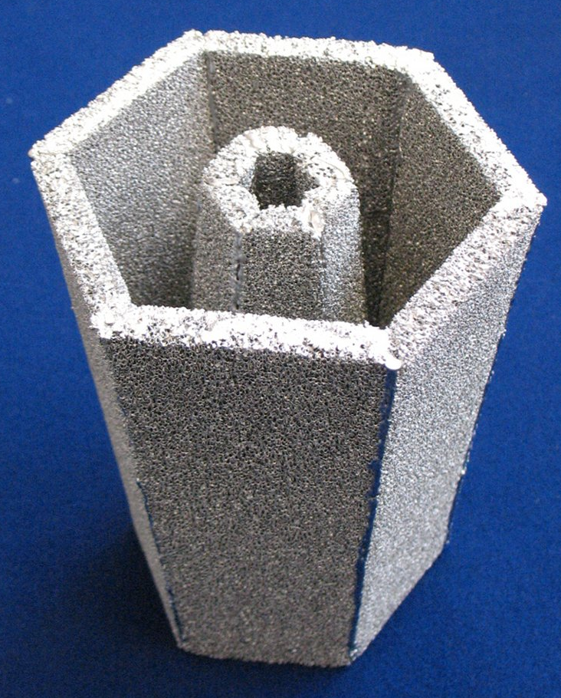

- Coating a polyurethane foam with a metal powder-binder suspension

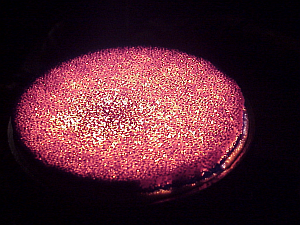

- Production of the metal foam by debinding (chemical/thermal) and sintering

- Flexible material selection - almost all metals or alloys available as powder can be processed

- Adjustable cell width and porosity

- Process suitable for series production

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM