Porous materials, such as open-cell metallic foams, grids or expanded metals, are used in many areas, such as H2 generation and storage. In order to meet the high requirements, the commercially available materials must be adapted in terms of their structure and composition. Fraunhofer IFAM Dresden has many years of experience in this field and has developed special coating technologies and heat treatments to produce passivation or functional coatings that ensure excellent durability and high reactivity.

Do you have a specific question about the coating of porous structures? Feel free to contact us by email or phone. We will find the best solution for you.

Coating of porous materials

- Starting material: industrially produced metal foam

- different options possible:

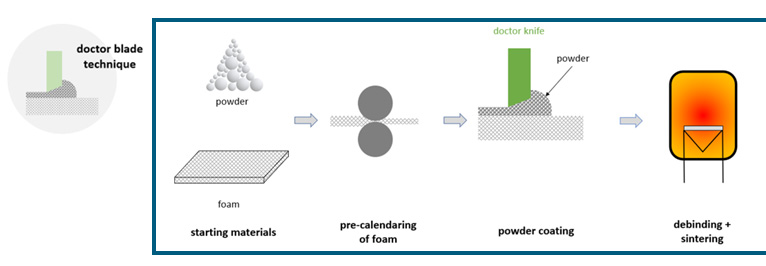

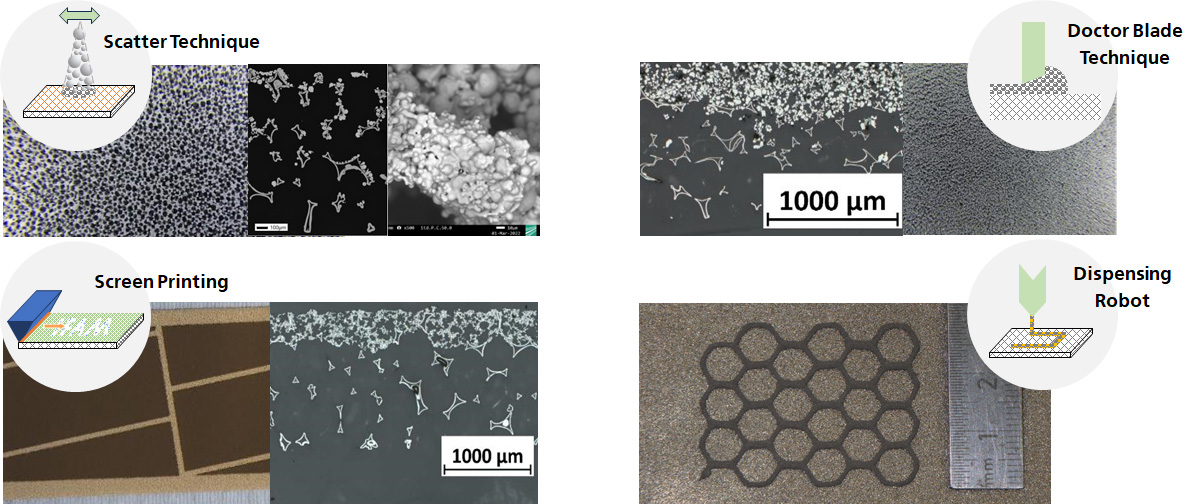

- Dry and wet processes

- Coating of the entire material or the material surface

- Coating with element powder or alloy powder

- Adjustable thickness, area density, pore size & porosity

- Machinability (cutting, bending etc.)

- Suitable for mass production

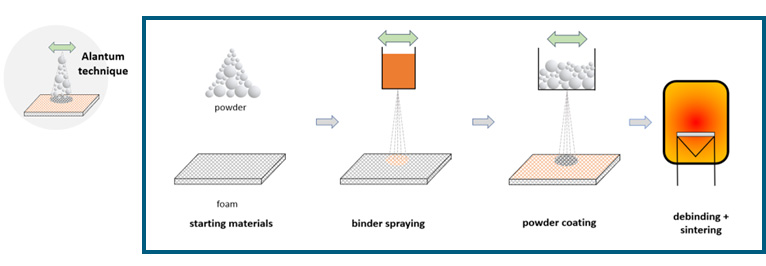

Manufacturing Process – varying coating technologies

Various coating technologies

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM