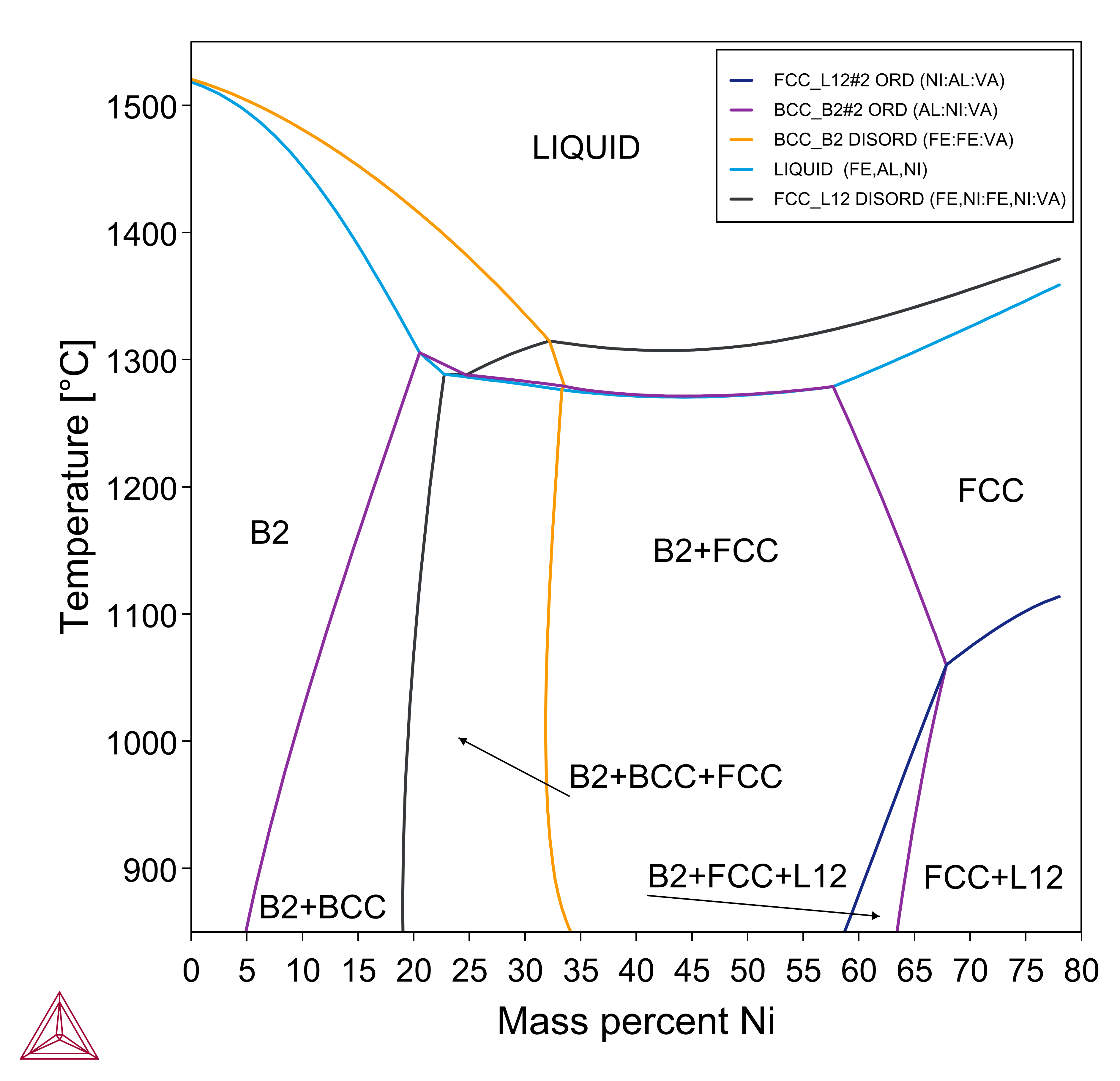

Thermodynamic calculations allow predictions about phase formation in materials during thermal processes, both during their manufacturing and under application conditions. The CALPHAD method (CALculation of PHAse Diagrams) enables the modeling of application-relevant materials beyond binary and ternary systems (e.g. Fe-Ni-Cr-Al-Y as a high-temperature alloy and Al-Mo-Nb-Ta-Ti-Zr as a high-entropy alloy) as well as the computer-aided simulation of their thermodynamic properties under defined conditions, e.g. chemical composition and temperature.

Simulations can be designed both in thermodynamic equilibrium (heat treatment) and for processes with rapid solidification, e.g. beam-based additive manufacturing or melt spinning.

The software used is Thermo-Calc with databases for relevant material systems, e.g. lightweight and high-temperature alloys, steels, innovative high-entropy alloys, and metal hydrides for hydrogen storage.

Fraunhofer IFAM Dresden has extensive capabilities and expertise for the experimental validation of simulation results, e.g. thermal analysis, heat treatment, metallography, scanning electron microscopy, and process analysis.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM