Targeted Improvement of Bio-Based Adhesives for Modern Applications

Bio-based adhesives made from renewable raw materials are becoming increasingly important. This is not only due to the scarcity of petrochemical resources but also the growing desire of industries and consumers for more sustainable alternatives. Bio-based adhesives are by no means a new invention; some of them have been successfully used for thousands of years. They rely on a variety of natural materials such as proteins (e.g., gelatin adhesive), starch, cellulose, or natural rubber. However, to utilize them for a broader range of modern applications, specific properties need to be improved intentionally.

Optimizing Adhesives for Modern Requirements

To enable the use of bio-based adhesives in various industries, specific properties must be optimized depending on the application. Properties that may need improvement include:

- Temperature Resistance: The adhesive must withstand high temperatures without losing its adhesive strength.

- Moisture Resistance: For certain applications, adhesives must be resistant to moisture to maintain their stability and strength.

- Optimized Processing Properties: Handling and applying the adhesive should be simple and efficient.

- Increased Adhesive Strength: Higher adhesive strength may be necessary for specific applications.

Innovative Solutions from Fraunhofer IFAM: Moisture-Resistant Gelatin Adhesives

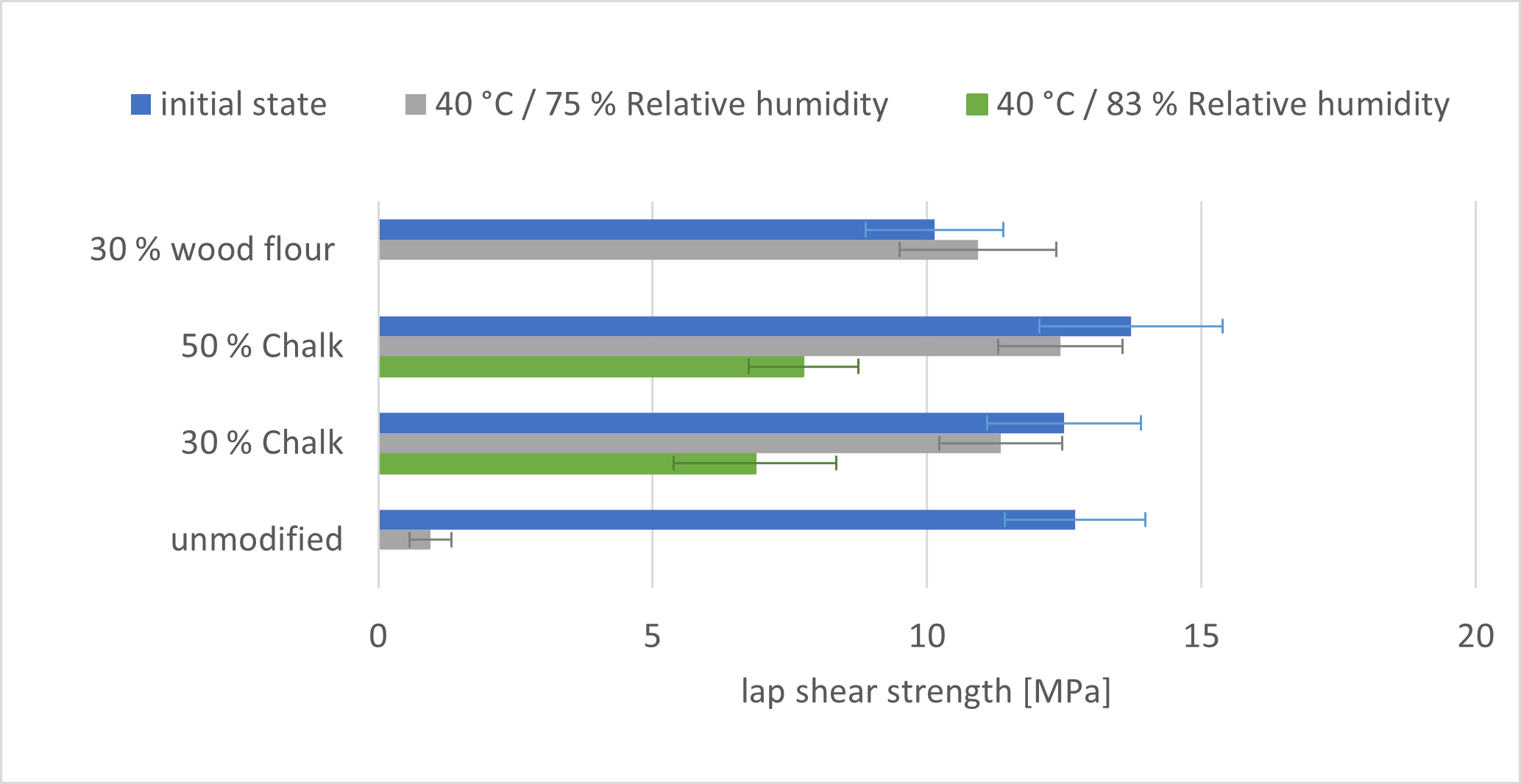

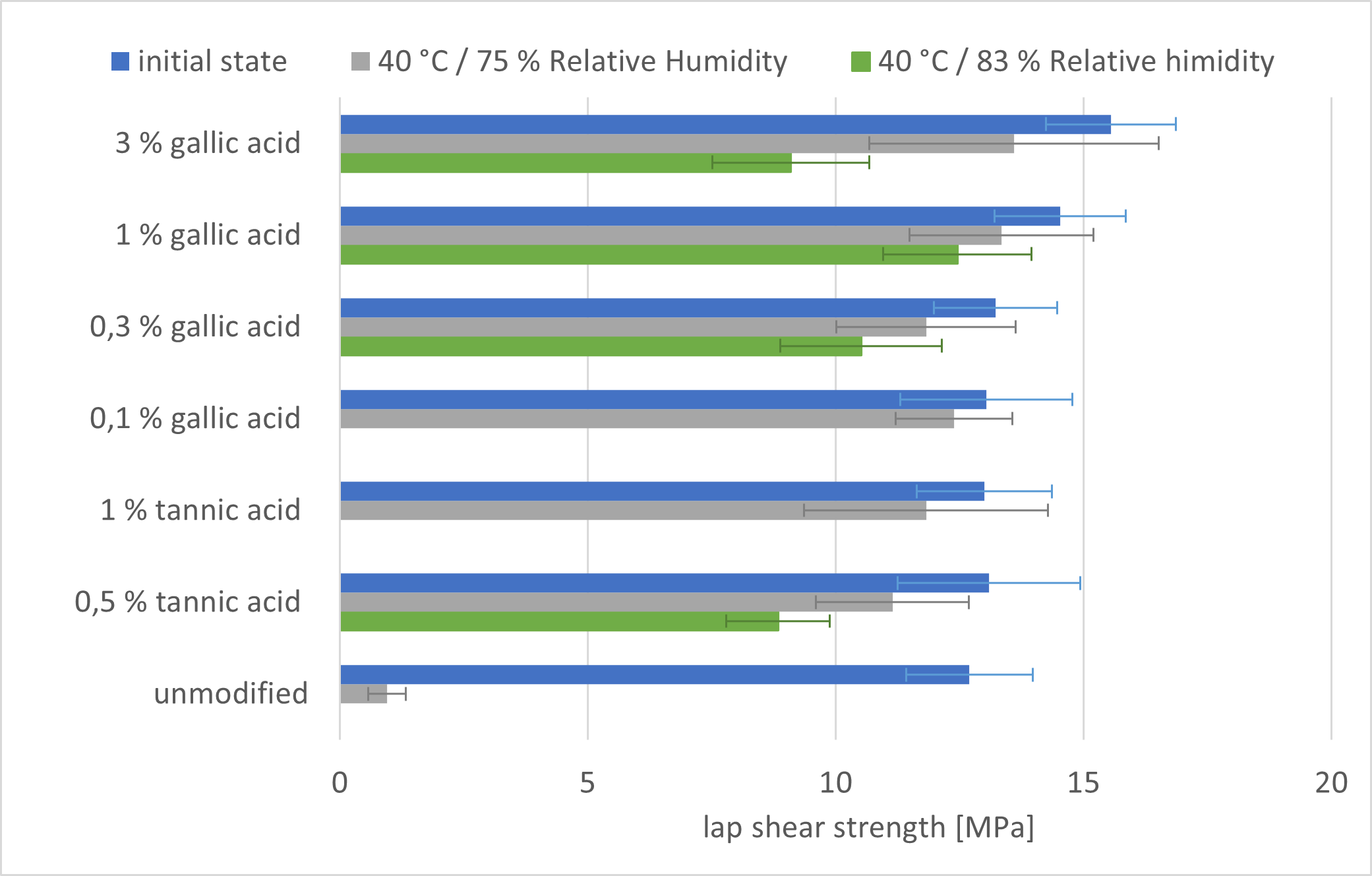

Gelatin adhesives made from collagen sourced from slaughterhouse waste have proven effective as adhesives. However, they have a high moisture absorption, which leads to a decrease in cohesion strength and thus adhesive strength. At Fraunhofer IFAM, research has been conducted on how to improve the moisture resistance of gelatin adhesives to explore their potential applications in structural timber construction. Two strategies have been developed for this purpose:

- Reduction of Water Absorption

- Improvement of Mechanical Properties in the Swollen State

Two approaches were successfully tested:

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM