Chemical Recycling of PET for Medium-Sized Enterprises

Mechanical recycling of PET has its limitations: Repeated thermal stress causes the quality of the material to deteriorate, which leads to so-called downcycling in other applications. An alternative is chemical recycling, considered an important step towards a sustainable circular economy. The large industry has recognized this as well and plans to invest 9.8 billion euros in chemical recycling technologies by 2030. The SKZ Plastics Center, in collaboration with the Fraunhofer IFAM, is developing a method to make chemical recycling of PET accessible for medium-sized enterprises.

"RezyBond": Innovative Method for Recycling Heavily Used Materials Developed

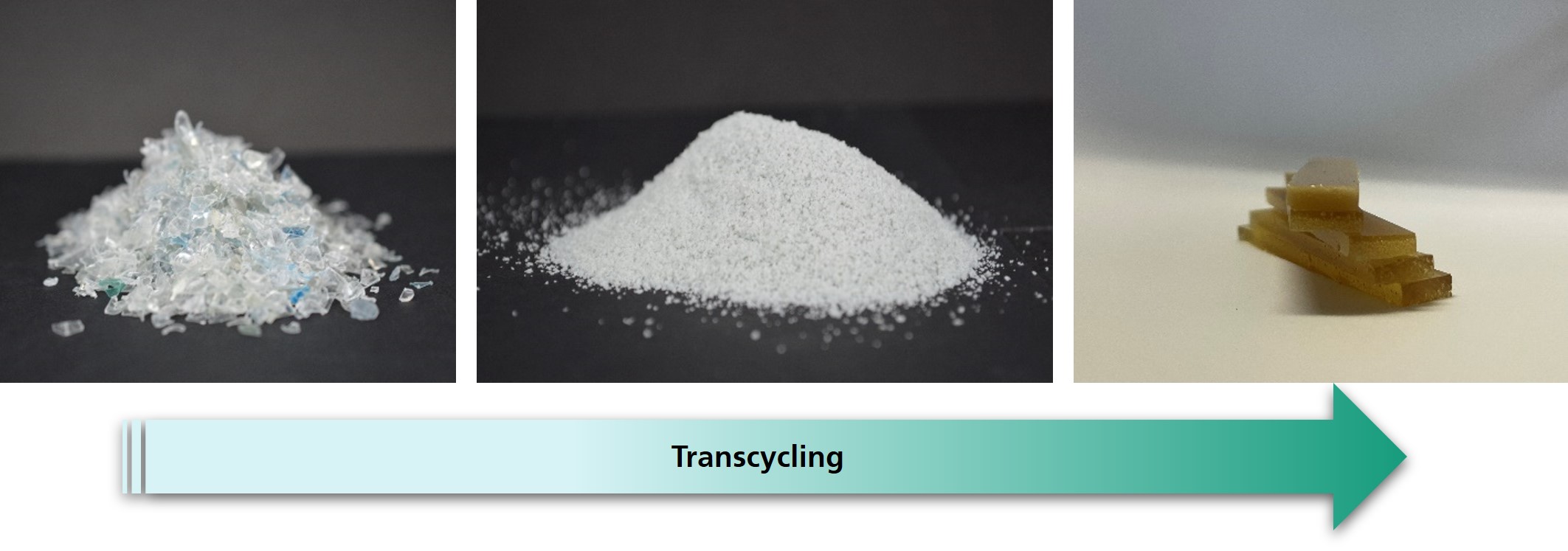

As part of the publicly funded IGF project "RezyBond," an innovative method is being developed to make heavily used materials reusable. By integrating various glycols into the PET structure, the material is broken down into smaller building blocks. Long-chain glycols, such as PEG300, can also be used, creating a wide variety of chemical precursors. This method has already been successfully tested in laboratory batch trials using various catalysts. Among other things, a naturally occurring substance available in large quantities and not classified as hazardous was used as a catalyst. The resulting oligomers can be used as full-fledged raw materials to create new materials without requiring additional processing steps.

From Laboratory to Production: Continuous Recycling Process for Cost-Effective Adhesives

The further course of the project will explore how the laboratory-scale results can be transferred to a continuous process using a dual-screw extruder. The focus for utilizing the resulting polyester polyols is initially in the adhesives sector, including 2K polyurethane systems. This material offers a cost-effective and resource-saving alternative to other synthetic raw materials.

The project generally opens up a new approach to various polyester polyols, which can be used as raw materials across different industries. The project, with the funding code 22951 N, runs from July 1, 2023, to June 30, 2025.

The "RezyBond" project represents an important step towards a sustainable and resource-efficient industry, benefiting medium-sized enterprises in particular. Chemical recycling thus becomes not only more environmentally friendly but also economically more attractive.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM