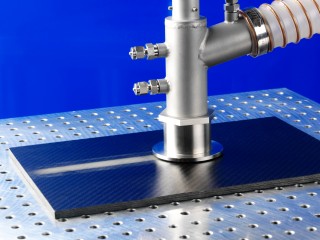

Contactless vacuum suction blasting of CFRP surfaces

INLINE-BLASTING PROCESSES FOR CLEANING, ACTIVATION AND REPAIR OF SURFACES | Classical compressed air blasting requires the use of blasting booths or complex temporary protective measures to clean surfaces or remove coatings. Much simpler is to use compact and mobile vacuum suction blasting prior to, for example, adhesive bonding, painting/lacquering, coating, or repair work. In this method an industrial vacuum system generates a reduced pressure in a closed head through which the abrasive is accelerated onto the surface and after the blasting process is immediately extracted again. This means that dust-free blasting processes can even be performed in-line under sensitive production conditions.

more info Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM