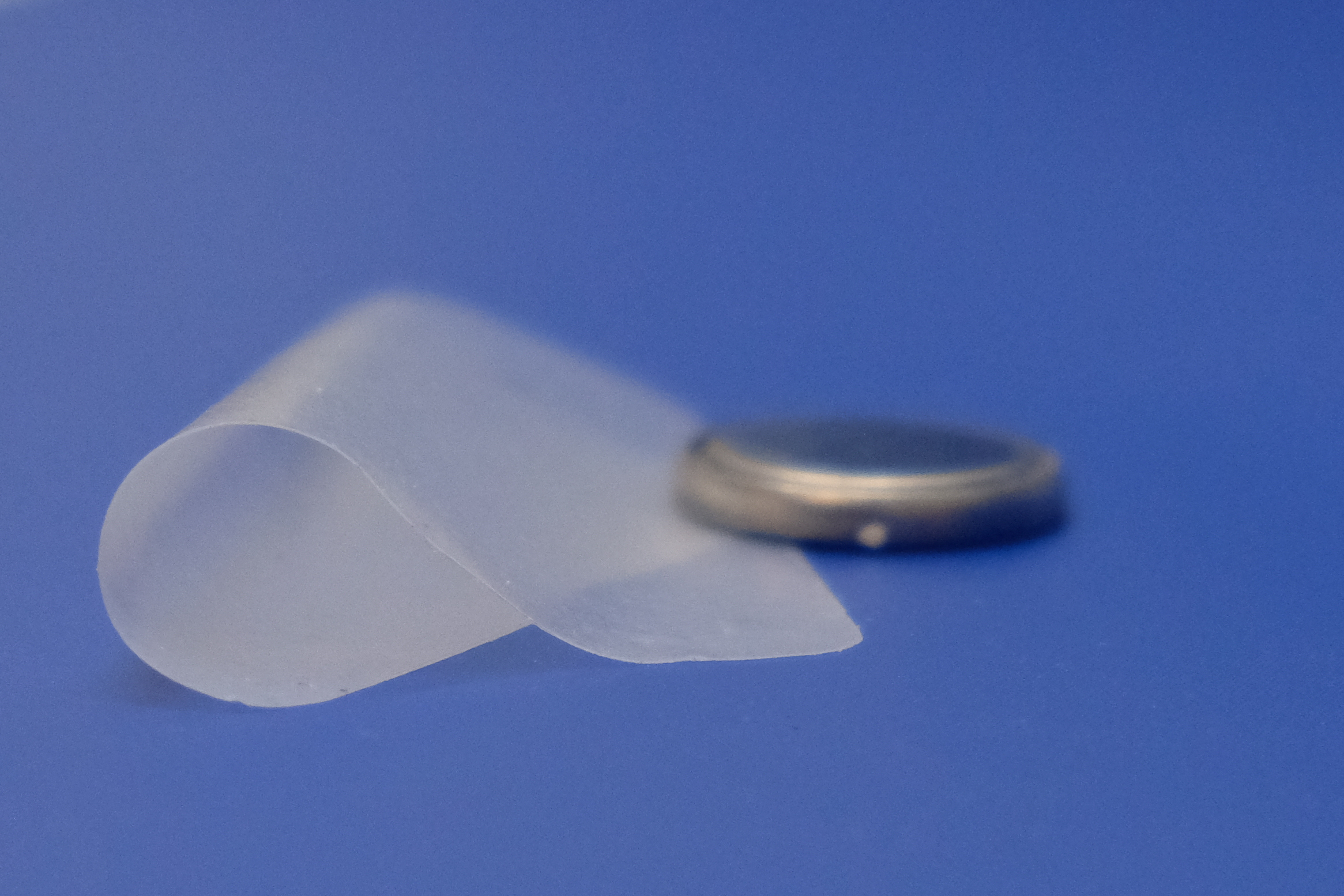

Dry production of polymer-based solid-state electrolytes

The solid-state battery (ASSB) is one of the next-generation technologies that could replace conventional lithium-ion batteries in the future due to its high energy density. The current challenge is scaling up the manufacturing processes for the individual battery components (e.g. the solid-state electrolyte). Fraunhofer IFAM is researching the solvent-free and therefore dry process route of polymer-based solid-state electrolytes by means of extrusion. The continuous mode of operation promises to implement an uninterrupted processing method in production chains. In addition, extrusion not only offers the possibility of producing on a kilogram scale, but also of reducing potential process costs by eliminating subsequent drying steps.

Scaled production of battery components

The ever-increasing demand for energy and the need to store renewable forms of energy require the further development of electrical energy storage systems. One of these further developments is the solid-state battery, which is one of the next generation of batteries. By replacing the liquid electrolyte of conventional batteries with a solid electrolyte, all components are solid. This has many advantages, e.g:

- Polymers are used as electrolyte materials due to their elasticity and malleability, as changes in the volume of the electrodes can be compensated for during the charging and discharging of a battery cell.

- Polymer-based solid-state electrolytes have good conductivity at elevated operating temperatures.

- A major advantage of polymer-based solid-state electrolytes over sulfidic or oxidic solid electrolytes is the wide range of solvent-based and solvent-free processing methods. For scaling, the investigation of the influence of the process parameters on product quality is of particular interest. The product properties must be maintained during scaling.

In order to understand these relationships better, Fraunhofer IFAM has developed an experimental setup ranging from kneading tests to investigate small quantities through to extrusion tests for production on a larger scale.

Preliminary tests of thermal processing and material stability with a laboratory kneader

As extrusion tests use a lot of material and are time-consuming, initial preliminary tests can be carried out using a laboratory kneader, e.g. to determine the material stability during thermal and mechanical stress and suitable process parameters (e.g. processing temperature). This makes it possible to derive process limits that can be transferred to the extruder in the next step. For example, the influence of the molecular weight of the polymer and the addition of the conductive salt on the thermal processing of polymer-based solid-state electrolytes can be determined. Our experts have published a scientific study on this subject.

Using recorded process parameters (torque and mass temperature) during the kneading tests, statements can then be made about the plasticisation effects and degradation behaviour of the polymer.

Inert, dry extrusion of polymer electrolytes

By transferring the process to the extruder, it is possible to process several kilograms per hour. The challenges arising during extrusion include the correct choice of material feed, screw design, and screw speed, as these have an influence on the product quality and the mixing quality of the end product. The expertise gained from the kneading tests allows suitable screw speeds, processing temperature and dwell time of the materials in the extruder to be determined with regard to material stability.

Our experts have published a scientific study on the production of PEO-based solid electrolytes using melt extrusion, investigating the influence of the screw design and process parameters on the product quality.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM