Energy-efficient, environmentally friendly functionalization of surfaces with light

The use of light to treat surfaces - such as cleaning or coating - offers many advantages over other surface treatments. UV light as a tool is non-contact, energy-efficient, chemical-free and has a disinfecting effect. And it is also cost-effective with high area coverage and homogeneity. In combination with other key technologies such as adhesive bonding and paint and lacquer technology, the use of VUV radiation opens up entirely new approaches to the development of innovative products and optimized product properties. Fraunhofer IFAM has many years of experience in the field of VUV technology with excimer and Hg emitters and supports companies in process development for their surface treatment.

The cleaning, activation, modification, and coating of a wide variety of surfaces is possible

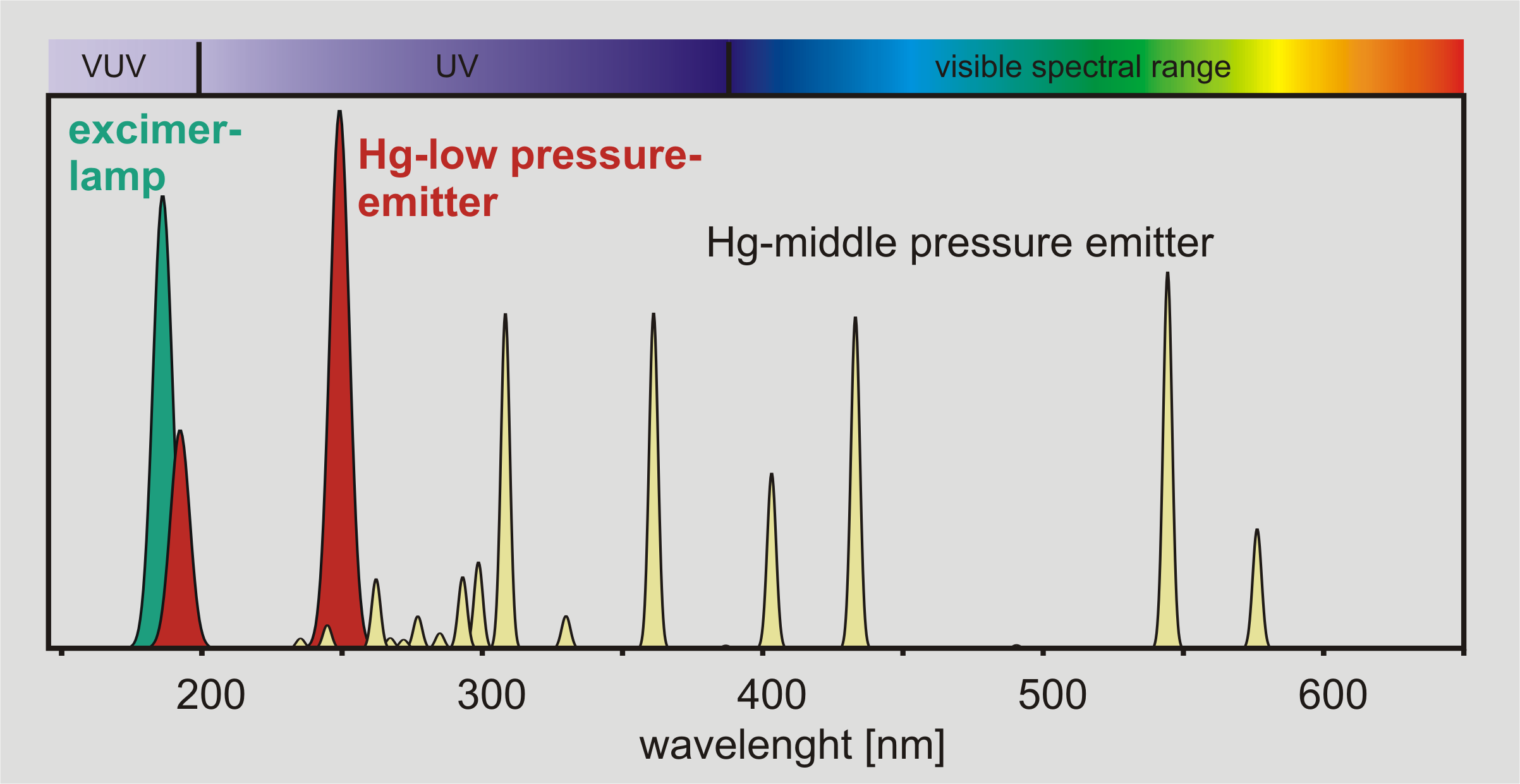

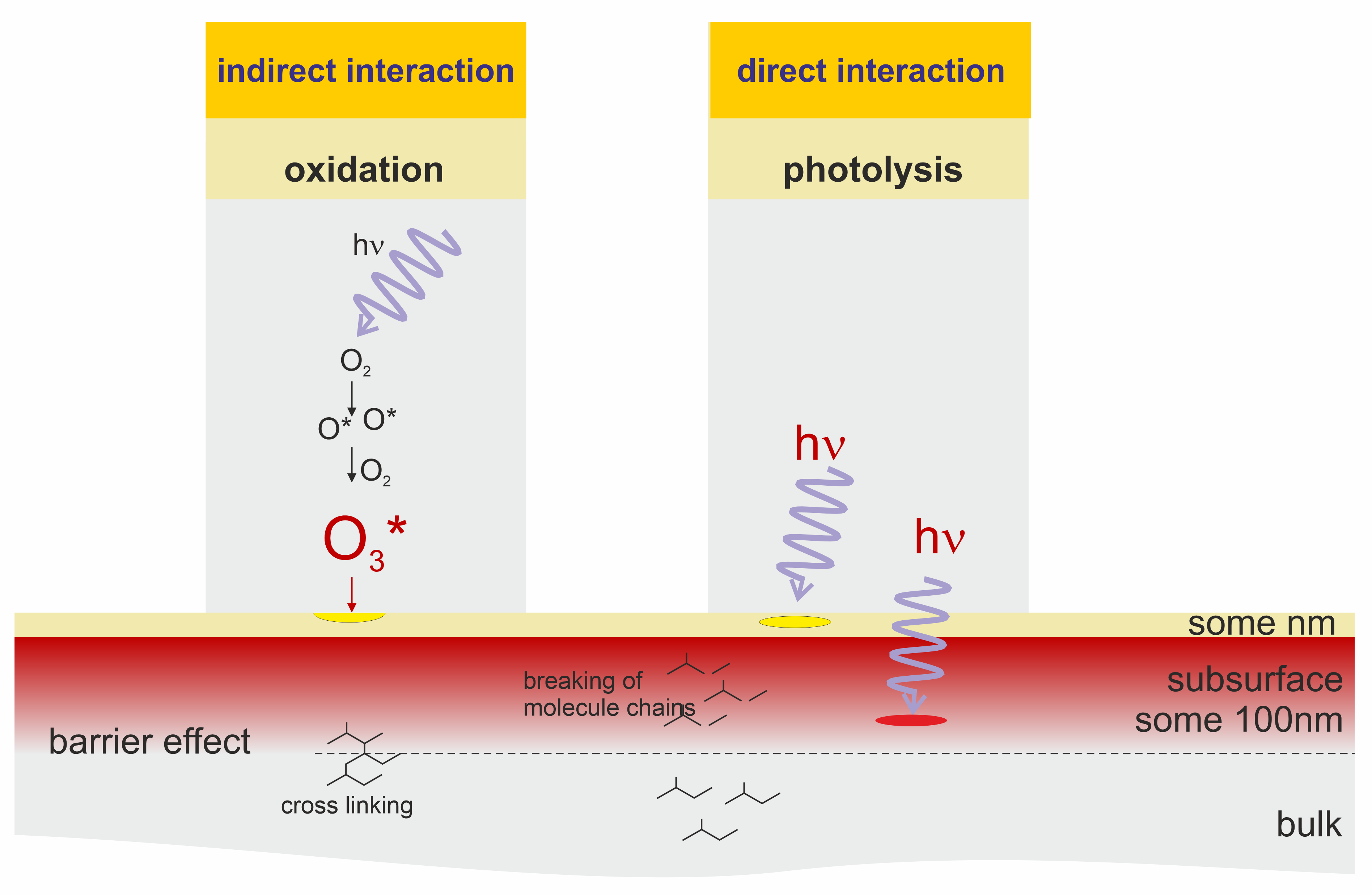

The demand for special functional coatings for components and products is steadily increasing in almost all industries. VUV light sources are particularly well suited for developing these coatings. They emit vacuum ultraviolet radiation (VUV radiation) with radiation emission below 200 nm and are characterized by the fact that their photon energy is sufficient to produce bond breaks in a material. This creates reactive molecular fragments that can react with each other or with the surrounding atmosphere. This is an ideal condition for modifying the surface properties of the material independently of the bulk material.

Typical surface treatments that can be performed with VUV light are:

- Surface cleaning

- Surface disinfection

- Surface activation

- Surface modification (SilMoLight® , OpSiLIGHT)

- Surface coating

Suitable light sources are, for example, incoherent excimer lamps or mercury low-pressure emitters (Hg emitters). They form the basis for the development of VUV light-based processes for surface functionalization and for the design of suitable equipment. A particularly attractive feature of the excimer lamps is their energy efficiency, since the emitters emit almost exclusively in the VUV spectral range and at the same time require a very low output power - compared with other pretreatment techniques. Moreover, since no additional chemicals are required for cleaning, activation and modification, VUV technology can make a valuable contribution to environmental protection.

From adhesive pretreatments to silicone modification and coatings - the range of applications is wide.

The applications that can be implemented by irradiation with VUV light are very diverse. For example, a wide variety of materials such as plastics, glass and metal can be functionalized. The component sizes and shapes are also very variable. Flat materials such as sheets or web materials, e.g. foils or textiles, can be processed particularly well, but also curved surfaces and 3D components.

Concrete application examples are:

- Optimization of the wetting properties of surfaces

- Corrosion protection coatings

- Tarnish protection

- Release coatings

- Adhesion promoting layers

- Barrier coatings

- Photocatalytically active coatings

- Color-neutral thin coatings (link to PDF "Color-neutral LightPLAS coatings)

- Antimicrobial coatings

The advantages of surface treatment with light summarized for you:

- Nearly cold process

- Contactless

- Large surface area

- High homogeneity

- Low investment

- Cleaning, activation and modification without chemicals

The focus of the research and development work is the use of light for surface treatment within the department "Plasma Technology and Surfaces" department, thus expanding the institute's technology portfolio to include another innovative, cost- and energy-efficient processing method. The fields of application in which VUV technology is already being used range from medical technology to automotive engineering and the textile industry.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM