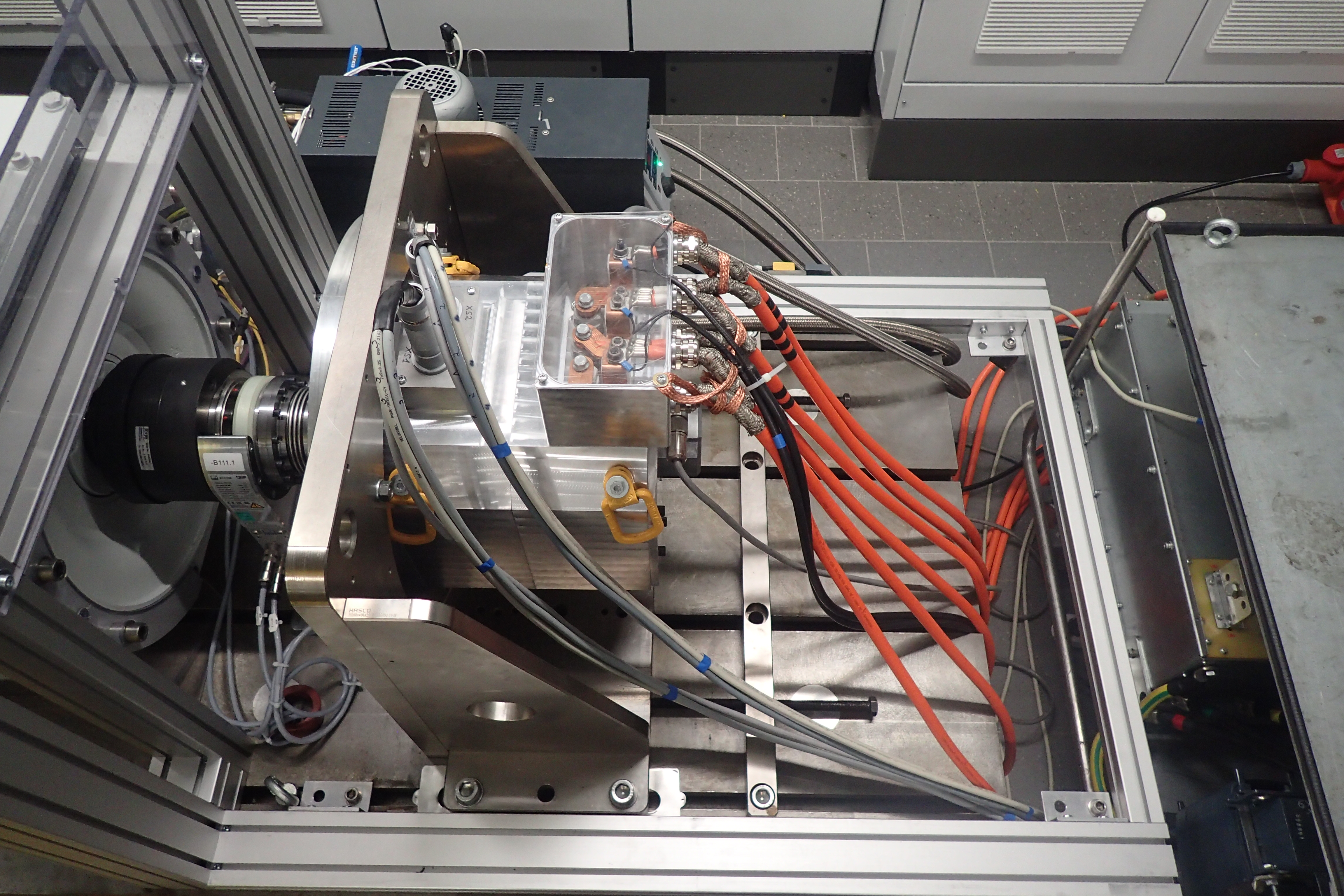

Development test bench for energy- and resource-efficient e-machines

Fraunhofer IFAM has been engaged in research within in the field of electric drive technology for many years. To identify optimization potential at an early stage during the development of electric machines, the institute has electric motor test benches in the power range <3kW and in the range from 20kW to 100kW. The performance of new technologies, developments or concepts in electric drives can be assessed here – this includes, in particular, the characterization of the operating behavior of electric machines (prototypes) beyond merely gathering of simulation data, through practical experiments.

For the electric drives of tomorrow

Our services are centered on technology assessment within the development field of electric drives. We assist the industry by transferring innovations from scientific research into practice and evaluating their effectiveness. This approach offers our customers a robust foundation for making informed decisions. Crucially, practical proof of performance is paramount - the functional demonstrator must validate its efficiency in real-world scenarios.

The advantages we offer our customers are paramount: they experience reduced risks in pre-series and development projects. Our decision-making tools are based on practical performance evidence. For example, early functional commissioning identifies faults and weaknesses before the extensive final testing, saving both time and money. Our flexible utilization options in terms of project scheduling and testing capacity (e.g. allowing test specimens to remain equipped during interruptions) provide advantages in the implementation of R&D projects. Through characterization and sensitivity analysis, we assess the impacts of manufacturing processes and new materials, such as the use of recycled permanent magnets, like recycled permanent magnets, to enhance the precision and efficiency of design processes. As part of special designs, we evaluate unique cooling conditions, such as direct liquid conductor cooling in the stator, to provide insights into optimizing heat dissipation.

Essentially, we provide our customers a solid basis for decision-making through practice-oriented testing, which minimizes risk and paves the way for successful innovations. Leveraging years of experience, our scientists bring their expertise in the development and design of electric drives. This enables us to support the transition of manufacturing innovations from science to the industrial implementation of electric drives of the future.

Examples of our testing options

- Verification of the performance and efficiency of prototypes

- Characterization of the performance characteristics

- Comparison and assessment of innovative components and approaches

- Functional testing and proof of concept of innovative e-machines

- Characterization and analysis of influence on innovation demonstrators

- Assessment of recycled materials

- Design and setup of test environments with for heat dissipation optimization

- Provision and analysis of measurement results for data-supported applications

- Analysis of manufacturing and material influences

- Long-term tests to determine ageing on components such as bearings, laminations, magnets, insulation, conductors and electrical joints

- Concept development for the qualification of machine components

Please contact us for more information on our service range.

More details on the technical data of the test bench can be found here.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM