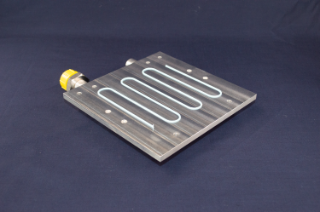

PLAQUE AND PROLIFERATION ASSAYS FOR EFFICACY TESTING OF ANTIBACTERIAL AND ANTIVIRAL SURFACES AND COATINGS | Multi-resistant germs have been a serious problem in healthcare for years. Covid-19, an infectious disease caused by SARS-CoV2, made the concepts of hygiene and disinfection an everyday topic around the world. Consequently, the need for antimicrobial technologies (antimicrobial coatings, UV disinfection) increased in many entrepreneurial sectors, including healthcare, automotive, construction, and public transportation. This wide range of applications presents different technological challenges. Fraunhofer IFAM therefore tests antimicrobial efficacy against model viruses, bacteria, and fungi according to customer-specific requirements.

more info

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM